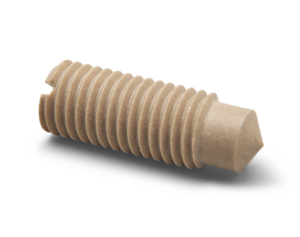

Machinable ceramices

In general, technical ceramics are known for their hardness and brittleness. These materials need to be grinded with special diamond tooling which makes detailed, precision parts very costly. There is, however, a subsection of technical ceramic materials that can be machined with standard metal working tools.

This group of machinable ceramics consists of machinable glass-ceramic (Macor), boron nitride and a form of aluminium nitride (Shapal Hi-M soft). These materials are produced by hot pressing material in large billets. The pressing of materials at high temperatures restricts the crystal growth of the materials, preventing large crystals from forming, and therefore leaving a fine structure. Fine particles can be plucked out of the surface of the material by carbide tools, leaving a smooth surface during the machining process.

Machinable ceramics are often used for small series and complex designs. The machinability of the materials comes at the expense of other material properties. Shapal Hi-M soft for example has a lower thermal conductivity and lower hardness than aluminium nitride. For the right choice of material, it is important to take all aspects into account when making a decision. Sourcing ceramics can support you in this process.